Impact Sockets

The range of impact sockets Cromwell stocks features big name brands, such as Kennedy, PCL and Facom. With both standard and deep impact sockets available, you'll be sure to find the right tooling solution for your requirements.

What are impact sockets?

Impact sockets are high strength sockets designed for use with impact wrenches. Unlike standard handheld wrenches, impact wrenches use a powered pneumatic motion which caused jolting vibrations as it generates large amounts of torque. The increase in forces would be enough to shatter standard sockets with use.

The design of impact sockets is much the same as standard sockets and they come in similar sizes, shapes, and depths. Their key difference is that Impact sockets, unlike their counterparts, are made from chrome molybdenum, which is a lot less brittle than chrome vanadium (the material generally used for standard sockets) which makes them able to handle the increased forces generated with an impact wrench.

Types of impact sockets

As is the case with standard sockets impact sockets, come in various shapes, depths, and sizes. To help differentiate one socket from another.

• Square socket A socket with a square recess designed for connecting with square fasteners.

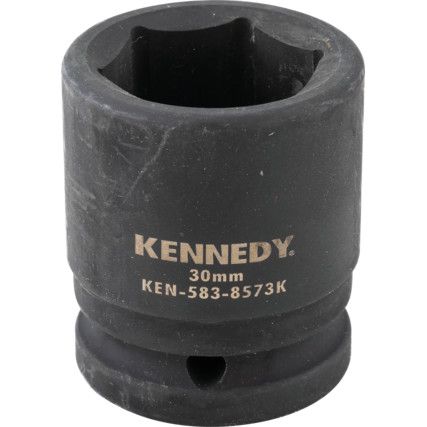

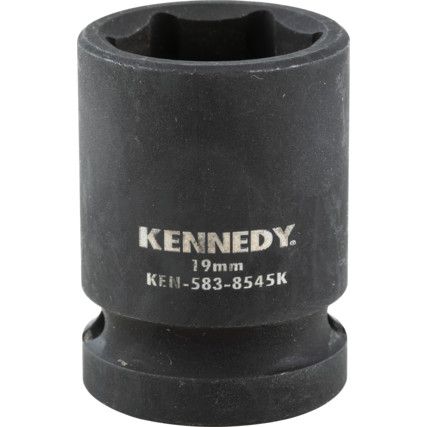

• Hex socket A socket with six sides resembling a hexagon when viewed straight on.

• Double hex socket A socket resembling two hexagons overlaying each other. Features twelve sides.

• Torx socket A socket that features a 6-pointed star shape.

• Deep sockets Designed for fasteners that are hard to reach, these sockets come in a range of depths.

Considerations when choosing a socket set

• Drive shape - Most common type of drive shapes are square and hex drive, this is imperative as getting this wrong won't allow the socket to connect to your impact wrench or tool.

• Drive size - Common sizes include 1/4-inch drive, 1/2-inch drive and 3/8-inch drives. Much with drive shape this will determine whether the socket fits or not.

• Socket type - Sockets commonly come in square, hex, torx and double hex types, suitable for a variety of fastener types. Selecting the right type of socket type for the fastener ensure that you will be able to complete the job without delay.

• Socket size - Sockets come in various sizes with both metric and imperial measurements available for every size of fastener.

• Socket depth - Deep sockets allow to reach fasteners that are fixed in position where the bolt protrudes beyond the reach of a standard socket.

FAQ

What impact sockets do I need?

Much like regular sockets, choosing the right impact socket for the job has several factors than need consideration. Firstly, the type of fastener, nut or bolt? Depending on this you may need to consider the depth of your socket choice. Nuts fastened over long bolts will need a much deeper socket to accommodate the extra thread on the bolt. The size of the fastener is also a key consideration to take into account as the socket should grip the fastener with very little or no wiggle room. Impact sockets, typically, fit a little tighter to the fastener and this results in less stripping.

Can you use impact sockets on a regular wrench?

Whilst impact sockets are better suited to impact and powered wrenches, they can also be used on manual hand tools as well, which makes them incredibly versatile tooling solutions. They also deal a lot better with increased torque and feature thicker walls, which can also have a downside when working with hand tools as working in tighter spaces becomes a little harder.

Can you use non-impact sockets on an impact wrench?

This is a sure-fire way to break your regular sockets... So no! regular sockets are made from chrome vanadium steel which whilst strong enough to deal with regular hand held ratchet and torque wrenches, will not be able to deal with the hammering vibrations of an impact wrenches pneumatic operation and are highly likely to crack and/or shatter with use. The increased forces are caused by the impact (hence the name) of the hammer in the wrenches' mechanism impacting on the anvil as it rotates and generates torque.

Are impact sockets stronger than regular sockets?

The short answer is yes! Impact sockets are normally manufactured from chrome molybdenum. Standard sockets are manufactured from chrome vanadium steel and whilst strong enough to deal with the torque being generated from a standard wrench, it will not be able to withstand the higher impact and forces in effect due to its brittleness and may shatter if used in impact wrenches.